Whether you notice them or not, metal roofs are everywhere. You probably wouldn’t normally think to look at the roof on a home, but if you take a drive down any road in any city, you’re likely to find a house or building donning some kind of metal roof.

But how much do you know about metal roofing? Did you know that it’s a low-maintenance roofing option that can last decades? Or that you can choose from a variety of shapes, looks, and styles, such as standing seam or stamped metal roofing?

At Sheffield Metals, we know how important it is to choose the best roofing type for your needs, which is why we think explaining the basics of metal roofing will assist in your decision-making process.

In this article, we are going to discuss:

- Reasons to consider or choose a metal roof

- Common roof terms and definitions

- The different uses and applications of metal roofing

- Types and options available with metal roofing

Benefits and Advantages of Metal Roofing

There are a number of reasons to choose metal roofing over other materials, like asphalt shingles, tiles, or concrete. While metal roofing might be the best choice for some home or building owners, we understand that it’s not always the best material for every consumer. The best way to know if metal roofing is a good match for you is to consider some of the most common reasons people decide to buy them.

Longevity

Metal roofing is specifically engineered to last decades longer than any other roofing material. Actually, many consumers ultimately decide to purchase a metal roof because it’ll be the last roof that they ever have to put on their home or business. Depending upon the type of metal material used, most metal roofs last 50+ years without any extreme signs of degradation or corrosion.

Durability

When compared to different materials like wood, concrete, plastic, or glass, metal easily stands out as the strongest and most durable. If properly installed, metal roofing is designed to withstand:

- Strong winds

- Rain and moisture

- Snow

- Hail

- UV exposure

- Mold, algae, mildew, etc.

- Rodents and other animals

Not to mention, metal roof materials are often Class A fire-rated and noncombustible, meaning the fire resistance is the highest grade possible. This proven durability against common roofing threats is one of the fundamental reasons metal roofing is so popular.

Maintenance

The level of upkeep needed to maintain a metal roof is generally minimal, especially if the roof was correctly installed. General upkeep would include looking for leaves, branches, and other debris that could get stuck on the roof and in the gutters around once a year and after strong storms. In the event that dirt or other stains do not come off with rain, there are methods to clean your metal roof. Also, a concealed fastener roof will generally have less upkeep than an exposed fastener metal roof.

Eco-Friendly

There are a number of reasons that metal roofing is environmentally friendly. First, most metal is highly recyclable, meaning that any tear-off metal, old panels, or even manufactured excess scraps can be recycled and used in future products. These metal materials can either come as pre-consumer or post-consumer recycled content:

- Pre-consumer recycled materials – Scrap content during the manufacturing stage that has been recycled for future use.

- Post-consumer recycled materials – Excess materials that have already been in the possession of a consumer at one point in time and have been recycled for reuse.

Second, there are several metal roofing materials, including aluminum, that are made of already-recycled metal. In fact, nearly 95% of all aluminum roofing is made up of previously recycled materials.

Lower Cost in the Long-Term

It’s true: Metal roofs are more expensive upfront as a one-time cost versus the cost of asphalt shingles or tiles. However, as mentioned before, metal lasts decades (60 years in some cases), while asphalt shingles last anywhere from 15 to 20 years. One metal roof can easily outlast at least three asphalt shingle roofs.

These two photos represent a 60-year cost comparison between mid-range shingle roofing (three in total) and metal roofing (one in total). In this scenario, the mid-range cost for one architectural shingle roof is around $8,700+ and the cost for one 24-gauge steel standing seam roof with a PVDF paint system is about $17,400+. Even if the shingle roof lasted 20 years, you would need to pay for a shingle roof about three times and a metal roof about one time in a 60-year span, making the metal roof a more economical choice.

Warranties

One of the best parts of owning a metal roof is the variety of warranty options made available by metal manufacturers and suppliers. Two of the most common are weathertight warranties (covers leaks in the roofing system) and paint warranties (covers certain levels of degradation of the paint system that coats the metal substrate). Warranties can vary quite a bit depending on your environment, the panel profile choice, the type of roofing material used, and the type of paint system on the coil. Be sure to thoroughly read the warranty documents ahead of time and ask questions before you buy.

Note: Weathertight warranties are only available for commercial projects. Learn more here.

Metal Roof Components, Accessories, Parts, and Definitions

In order to better understand a metal roof and how it works, let’s start with some components, accessories, and other important roofing terms and definitions. (Note: The definitions in these sections are in alphabetical order.)

Metal Roofing Components Definitions

- Accessories – Accessories are the additional components needed to complete a metal roof installation. This includes fasteners, clips, underlayment, sealant, pipe boots, and anything else beyond the metal panels that make up a roofing system.

- Metal coils & sheets – Metal coils are long, continuous metal rolls that have been treated and/or coated with a paint system. All metal roofing starts out as coil, which is then rolled out, processed (slit, cut-to-length, etc.), and then rollformed into panels for installation.

- Panels – Panels are rollformed pieces of a metal coil that have been shaped into the desired profile/ribbing structure and are ready to be connected or seamed together to form a metal roof.

- Profile – The shape that the metal panels are formed into. The profiles are what determine how the panels fit, connect together, and are attached to the structure.

- Rollforming machinery/equipment – The machinery, either in-plant or portable, that forms and shapes the coil into individual panels.

- Seam – The side rib at which two metal panels come together and are connected. Seams are formed using a rollformer and are then snapped or mechanically seamed together.

Metal Roofing Accessories Definitions

- Butyl tape – Butyl tape is a form of sealant that is commonly used for metal-to-metal applications and trim purposes. It differs from gun caulking sealants because it’s in the form of two-sided tape and seals by compression.

- Clamps– Clamps are small metal parts that are tightened and attached to the top of the metal roof at its standing seam. These clamps have screws at the top used to attach extra roofing items such as a snow retention system, solar panels, satellite dishes, signs, AC units, etc.

- Clips or cleats – Clips are used to attach the metal roof panels to the deck. Clips are put on the standing seam portion of the bottom panel, which is then attached to the roof deck by fasteners. After the clip is put on the bottom panel, the top panel is placed over the clip and the two panels are snapped together or mechanically seamed into place, which securely attaches it to the structure.

- Fasteners – Fasteners are the screws used to attach the metal roof to the roof deck during installation.

- Pipe boot – A pipe boot is the cone-like fitting that is installed around an exhaust pipe that exits through the roof. These products are typically made up of EPDM rubber (silicone is also available for high-temperature applications). The pipe boot, which can be purchased in a color matching the roof, is cut to fit the diameter of the exhaust pipe and is then sealed to the pipe and the metal surface.

- Rivets – Rivets are similar to fasteners, but require a special rivet gun to install.

- Sealant or caulk – Sealants are used during installation to seal out water, dirt, wind, and other substances that can get into small spaces, making the roof as water-tight as possible. Sealants, which are typically made up of silicone or polyurethane, come out of the tube as a flexible sealing compound that will cure after application. Most sealants are available in colors matching the roof panels.

- Underlayment – Underlayment is the layer of material that goes underneath the metal panels and provides protection from water and moisture, ice, high temperature, and vapors. Underlayment is generally installed mechanically or self-adhered with a glue backing on the roof deck. While there are many different types of underlayment, common materials are felt, synthetic (polypropylene or polyethylene), and fully-adhered peel and stick.

Parts of a Metal Roof Structure & Definitions

- Cricket – A peaked saddle construction installed between a chimney and the roof surface to prevent the accumulation of snow and water.

- Curb – An accessory used to mount additions (AC units, fans, signs) and provide a level resting structure on a sloped roof.

- Dormer – A roof structure that projects vertically beyond the plane of a pitched roof (often contains a window).

- Drip edge – A long piece of metal that is installed so water runs into the gutter and away from the fascia.

- Eave – A portion of the roof that extends past the supporting wall.

- Fascia – The trim right below the roof that runs the perimeter of a structure to help keep water from running into the structure.

- Flashing – Sheet metal that is used to seal different portions of the roof, i.e. chimneys, valleys, etc., and provide extra weather-tightness.

- Gable – The triangular section of a wall between the edges of a sloping roof. The trim occupying this article is typically called “gable or rake trim.”

- Hip – The external or jutting angle at which two sloping roof panels meet.

- Pitch – The slope of a roof, which is measured using the roof’s rise divided by its run.

- Ridge – The highest portion of a roof where at least two roof panels come to a point (commonly a horizontal line).

- Roof decking – The base or foundation that the underlayment and roofing material are attached to. Common roof deck materials are metal, plywood, and oriented strand board (OSB).

- Valley – The internal angle at which two sloping roof planes meet.

Common Uses and Applications for Metal Roofing

Metal roofing has the reputation of only being used on large industrial or commercial structures. While it’s true that metal is a good option for these applications, metal roofing goes far beyond this, as it can be used on homes, architectural buildings, and agricultural structures. Let’s discuss more common uses and structures to look for the next time you’re out in your city or town.

Commercial Buildings

One of the biggest reasons metal roofing is commonly chosen in commercial applications is due to its superior weather resistance to wind and water, especially in areas where hurricanes or other tropical weather is a concern. Even when the structure isn’t in a tropical location, metal roofing gives business and building owners the peace of mind that their roof is destined to last and not need constant upkeep.

Common uses include:

- Hotels

- Hospitals

- Schools and universities

- Churches

- Government buildings

- Military structures

- Restaurants

- Stores

- Offices

Residential Projects

The residential market is booming as homeowners begin to realize that metal roofing will actually save them money in the long run. A lot of homeowners don’t think their roof is big enough to warrant a metal roof, but we are here to tell you that the size of your roof doesn’t matter. Metal roofing systems can be used on something as small as a shed or mailbox.

There has also been an increase in metal being used as an accent, awning, or as a portion of the roof. Be sure to consult with the manufacturer before a contractor installs two different roofing materials together, as they could potentially react with one another.

Architectural Projects

Since metal roofing begins as a metal coil or sheet, it has the ability to be formed and cut into many different shapes, sizes, and lengths. This variety — along with the durability, variety of colors, and eco-friendly qualities — provides architects will many benefits to using metal to create aesthetically pleasing structures.

Structural Uses

Have you ever been inside a warehouse, factory, or other industrial building where you look up and see the roof from the inside? This is a good example of structural metal roofing, which is when metal panels are installed over open framing or on structures that span long lengths and are attached directly to the frame or purlins (additional support beams added to the roof frame).

Agricultural Buildings

Like structural applications, barns and other agricultural buildings are common uses for metal roofing. Agricultural structures traditionally use an exposed fastener or lap seam profile, which is when the ends of the panels overlap each other and have sealant or exposed fasteners holding the two panels together.

Metal Roofing Types and Options

The popularity of metal roofing is often due to its versatility, variety of options, and ability to be customized for each individual structure, which includes color, shape, style, and much more.

Metal Material Types

Metal is a very broad term when it comes to roofing, especially because there are nearly 100 metals on the periodic table of elements. Some of the most commonly used metal roofing materials used in the industry are:

- Galvalume (steel)

- Galvanized (steel)

- Stainless steel

- Aluminum

- Zinc

- Copper

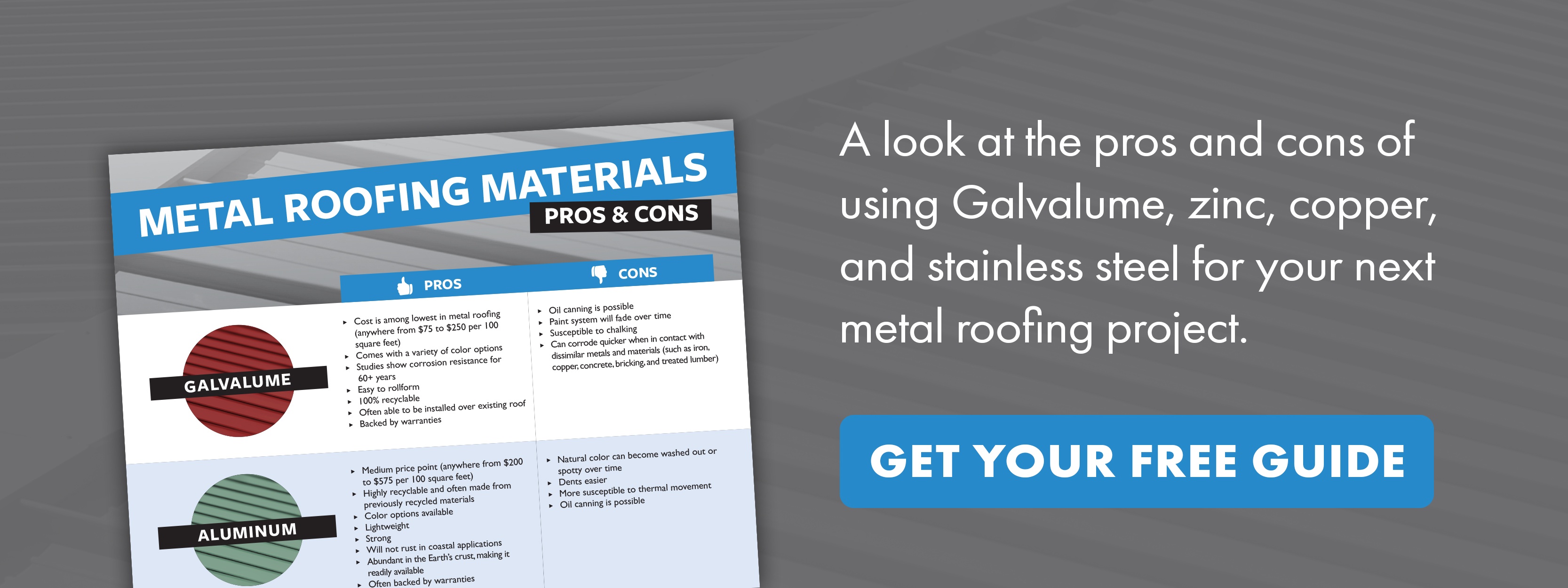

All of these metals are good options, but there are different pros and cons associated with each one. Make sure you read up on metal roof material options to determine the best one for your location, style, and needs.

Metal Roofing Panel Styles

Standing Seam – Standing seam metal roofing refers to metal panels interlocked together at the edges to form a seam, which stands vertically. A true standing seam system uses the concealed fastener method of installation, meaning the clips and fasteners are hidden beneath the surface and not visible to the naked eye. This is what sets it apart from all other metal roofing. Standing seam roofing is considered the superior, higher performance choice when compared to exposed fastener metal roofing.

Exposed Fastener – Exposed fastener metal roofing, which is considered the less expensive and more economical choice, is installed with the heads of the fasteners visible on the top of the panels. When an exposed fastener roof is installed, the fastener goes directly through the metal and into the roof deck. Exposed fastener systems are classically used in agricultural or industrial applications.

Stamped Profiles – If you like the look of shingles or more textured surfaces but still want the longevity, cost, and durability metal offers, it’s possible with stamped metal profiles. There are many different stamped options to choose from, including:

- Shake

- Shingles

- Tiles

Standing Seam Profile Options

Snap-lock – Metal roofing panels that have been carefully rollformed with specific panel profile edges that snap together and require no hand or mechanical seaming during installation. Snap-lock seams tend to be a little more popular in the roofing industry because they are engineered to defend against the elements while making installation a little easier on the contractor.

Mechanical seam – Mechanically seamed panels are also rollformed with specific edges that line up with each other on the roof. Once the two edges are put together, a hand or robotic seamer is used to bend the edges and lock the panels together. The locked seam resembles the shape of a paper clip. There are two kinds of mechanical seaming:

- Single lock / 90-degree seam – one fold of the seam

- Double lock / 180-degree seam– two folds of the seam

Tee panel – A type of standing seam where the two panels come together and are connected at the top by a cap, which is then mechanically seamed in place to lock the panels together. Once the seaming is complete, the top of the standing seam is in the shape of a “T”.

Nail/fastener flange – Nail flange (also referred to as fastener flange) is similar to a snap-lock panel system, but instead of using a clip to attach the panel to the roof deck, it’s directly fastened down to the deck through the male leg of the metal panel. Once the fasteners are in place, the female leg of the panel snaps over the entirety of the male leg, which hides the fastener head.

Metal Paint Colors and Finishes

Having control over the color and overall look of your structure is one of the most appealing parts of choosing metal roofing. Because of the overwhelming demand for both bright and earth tones on roofing systems, paint companies (like Sherwin-Williams) create high-performance paint systems that add style to a home’s exterior while still reducing chalking, fading, chipping, and other color degradation.

In addition to virtually every color being an option, you can also special order the finish of your choosing. If you want a blue roof with a matte finish, a silver roof with a metallic finish, or a white roof with a glossy finish — all of it is possible with a metal roofing system.

Common Metal Thicknesses

The material that makes metal roofs comes in many different thicknesses and is dependent on the application:

- Standing seam systems typically use between 22 and 26-gauge steel, with the most common thickness being 24-gauge (or .032″ and .040″ aluminum).

- Exposed fastener systems typically use 26 or 29-gauge material.

- Stamped shingles typically use either .019″ or .024″ aluminum or 29-gauge steel.

Panel Rib Rollers (Striations)

Rib rollers are the “patterns” or striations rollformed into a metal roofing panel between the seams. These can be used to assist with the installation of a metal roof or just for curb appeal. Common rib rollers include:

- Ribbed – Some shape or indentation between the seams

- V-Ribs – “V” shaped panel indents

- Bead – Longer, rectangular panel indents

- Pencil – Circular panel indents

- Striated – Small consistent indentation lines in the panel (can help reduce oil canning)

- Corrugated – Larger, constant waving of the metal panel

- Clip relief – A stiffening rib adjacent to the seam that allows the space for a clip

Final Thoughts on Metal Roofs

If you’re new to metal roofing or just beginning to do your research on the benefits of this roof type, it can a complex topic. It’s true, metal roofing might not be for everyone.

But more often than not, it’s a good option for a home or property owner if:

- You want your next roofing purchase to be the last roof you have to buy.

- You don’t want to pay more in the long run to replace a shingle roof every 15-20 years.

- You want an eco-friendly, sustainable roof requiring little to no maintenance.

- You want a roof that is recyclable.

- You want a roof available in a variety of color, finish, or texture options.

At Sheffield Metals, we understand the importance of choosing the best roof for your home or business. We are here to answer your questions and help you decide. Contact us today to speak with our metal roofing specialists.